Section VI

Paragraphs 6-39 to 6-41

Generator SG-l/ARN. If sufficient SG-13/ARN output

within 0. 0065 percent. If any of the crystal frequen-

cannot be obtained, reset the stop on the attenuator

cies are found to be more than 0.0065 percent in error.

shaft (9, figure 6-10). With this stop set for a maxi-

it will usually be found that all the other frequencies

mum output of 200, 000 microvolt the attenuator dial

are in error in the same direction. A slight adjust-

will usually indicate that value with little error.

ment of C1534 at the bottom of the coarse frequency

oscillator should shift all the crystal frequencies so

that none will fall outside the 0. 0065 percent limits.

If any crystal still falls outside these limits insert a

Use extreme care in turning the attenuator dial

new crystal to obtain required frequency.

while the stop is being adjusted. If the dial is

turned too far, the U-shaped pick-up loop in

the attenuator may strike the final tank coil

and be damaged. This is usually evidenced by

a. Place all covers on the r-f chassis and tighten all

the CAR meter reading dropping to zero at the

cover screws securely. This is necessary to prevent

r-f leakage during alignment.

highest setting of the MICROVOLTS dial.

b. The r-f output is adjusted by comparing it with

the coil at the maximum setting of the MICROVOLTS

the output of a Signal Generator SG-l/ARN. Feed a

dial may be checked as follows. Refer to figure 6-13.

114.9 mc signal from Signal Generator SG-l/ARN in-

to an AN/ARN- 14 navigation receiver with a d-c

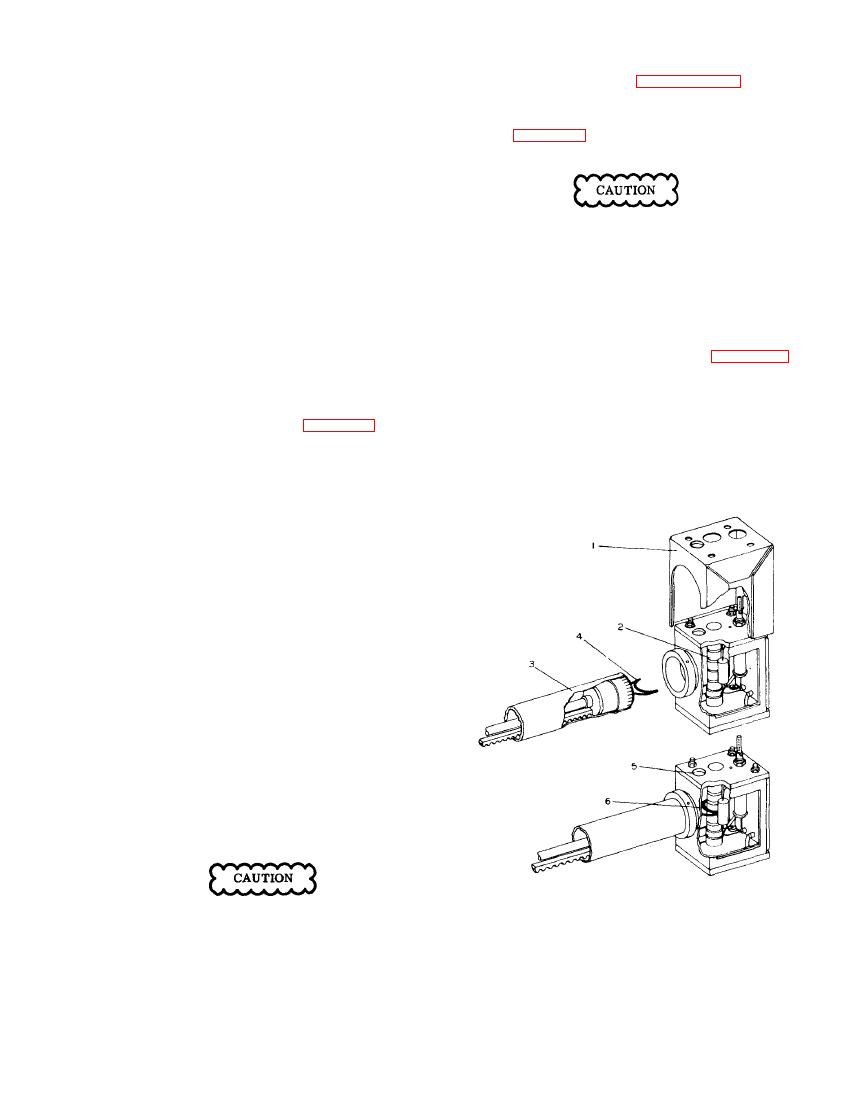

a. Remove the bottom r-f shield cover.

vacuum tube voltmeter connected to measure the re-

ceiver avc voltage. Use a 53-ohm 6-db pad in the

cable connecting the receiver to the SG-1/ARN to keep

b. Remove the four nuts and shakeproof washers on

the top of Z1502 and pull off the shield can (l).

the standing wave ratio low. See figure 5-1 for test

connections.

c. Shine a light through the hole (5) on top of the

housing and note the clearance (6) between the loop (4)

c. Set Signal Generator SG-l/ARN MICROVOLTS

dial to 500 microvolt and note avc voltage developed

in tbe receiver.

d. Substitute Signal Generator SG-13/ARN for the

SG-l/ARN using the same 6-db pad and adjust the

MICROVOLTS dial until the same avc voltage reading

is obtained. Adjust METER ZERO. The CARRIER

SET control should be adjusted to the red line prior to

this measurement. The MICROVOLTS dial should

read 1000. If not, loosen the dial set screws with the

Bristo wrench furnished and reset.

NOTE

.

The SG-l/ARN microvolt dial is calibrated

for use with a 6 db pad. The SG-13 micro-

volt dial is calibrated for a direct connec-

tion between NAV or GS output connectors

and receiver input.

A 53-ohm 6 db pad is used with the SG-13/ARN

output cable in this test only to insure proper

termination of the SG-13/ARN in case the re-

ceiver being used does not have exactly 53-

ohms input impedance. For this reason, the

SG-13/ARN MICROVOLTS dial must be set to

twice the reading of the SG-l/ARN microvolt

dial during this alignment procedure.

1

Shield can for Z1502 assembly

Take care to allow the signal from only one

2

Final r-f tank coil L1506

signal generator to get into the receiver while

3

Attenuator removed from collar

measuring the avc voltage. Adjust the signal

4

Pick-up loop

generator not in use to some other frequency

5

Inspection hole

while making measurements.

6

Point of normal 1/32 to 3/64 inch clearance

with MICROVOLTS set to maximum

e. Turn the SG-13/ARN MICROVOLTS dial to a max-

imum. This should give 200,000 microvolt which is

comparable to a 100,000 microvolt setting on Signal